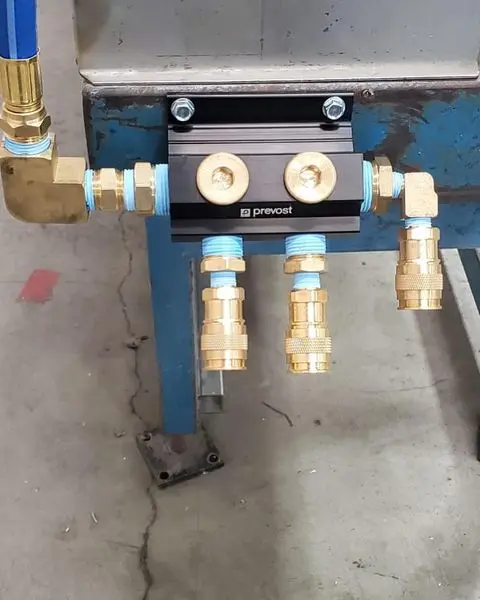

In the manufacturing industry, quick couplings are essential components that improve productivity, enhance safety, and minimize equipment downtime. These couplings enable fast, secure connections for fluid, gas, and power lines, facilitating seamless operation across various applications. Whether used in pneumatic, hydraulic, or fluid transfer systems, quick couplings play a crucial role in industries such as automotive, aerospace, food processing, and electronics.

Applications of Quick Couplings in Manufacturing

Pneumatic Systems

Pneumatic systems power a wide range of manufacturing tools and automation systems. Quick couplings ensure efficient, reliable connections between air lines and equipment, allowing for quick tool changes and minimal disruptions.

- Powering Pneumatic Tools: Quick couplings enable fast connections for pneumatic tools such as drills, impact wrenches, and grinders. This is particularly useful in automotive assembly, metalworking, and electronics manufacturing, where frequent tool changes are required.

- Automation and Robotics: Pneumatic actuators and robotic systems rely on quick couplings to supply compressed air, allowing for easy maintenance and reconfiguration of automation lines.

- Leak Prevention: High-quality quick couplings feature precision seals that prevent air leaks, maintaining consistent pressure and improving energy efficiency.

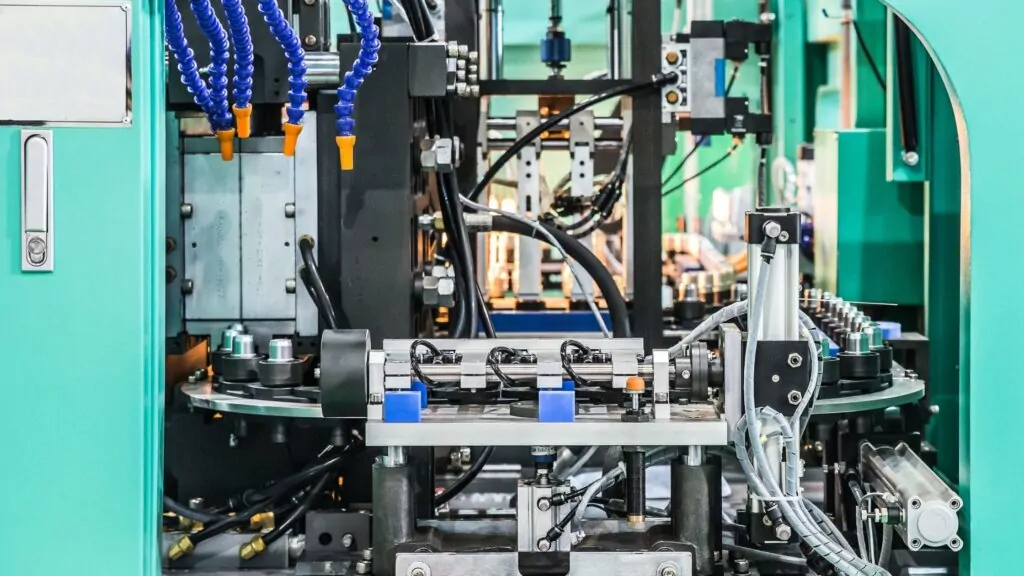

Hydraulic Systems

Hydraulic systems are critical in heavy-duty manufacturing operations that require high-pressure fluid power. Quick couplings facilitate fast, secure connections, reducing downtime and streamlining maintenance.

- Machine Presses and Injection Molding: In automotive, plastics, and metal industries, quick couplings simplify hydraulic fluid transfer, allowing for efficient mold changes and machine servicing.

- High-Pressure Operations: Quick couplings designed for pressures up to 10,000 psi ensure safe, leak-proof connections under extreme conditions.

- Maintenance and Testing: Quick couplings support pressure testing of hydraulic systems, ensuring optimal performance and safety.

Fluid Transfer Systems

Quick couplings play a vital role in handling coolants, oils, chemicals, and other fluids in manufacturing processes. Their leak-proof designs enhance efficiency and safety.

- Coolant and Lubrication Systems: Quick couplings enable fast connections in CNC machines and milling equipment, minimizing downtime during tool or fluid changes.

- Chemical Processing: Corrosion-resistant couplings facilitate the safe transfer of aggressive chemicals, ensuring durability and safety.

- Spill Prevention: Shut-off valves in quick couplings automatically stop fluid flow during disconnection, preventing spills and reducing waste.

Cooling and Heating Systems

Maintaining optimal temperatures is crucial in manufacturing. Quick couplings allow for fast setup and maintenance of cooling and heating systems.

- Injection Molding and Plastic Production: Quick couplings connect temperature control units to molds, regulating heat efficiently.

- Cooling in Metalworking: Processes like welding and CNC machining generate heat, requiring quick couplings for rapid coolant line connections.

- High-Temperature Applications: Quick couplings withstand extreme heat in ovens, kilns, and steam systems, ensuring durability.

Vacuum and Compressed Air Systems

Vacuum and compressed air systems are widely used in packaging, electronics, and precision manufacturing.

- Vacuum Systems in Electronics: Semiconductor manufacturing relies on quick couplings for contamination-free vacuum connections.

- Compressed Air in Packaging: Quick couplings enhance flexibility in automated packaging lines, allowing for rapid tool and material changes.

- Leak-Tight Seals: Ensuring airtight vacuum connections is crucial for precision processes, and high-quality couplings prevent leaks effectively..

Food and Beverage Manufacturing

Hygiene and efficiency are paramount in food production, making quick couplings an essential component.

- Sanitary Designs: Stainless steel or food-grade couplings prevent bacterial buildup and ensure easy cleaning.

- CIP (Cleaning in Place) Systems: Quick couplings enable rapid connection of cleaning solutions, minimizing downtime between production runs.

- Hygienic Fluid Transfer: Leak-proof couplings ensure safe handling of beverages, dairy, and other food products.

Automation and Robotics

As manufacturing processes become increasingly automated, quick couplings provide the flexibility needed for efficient production.

- Robotic Tool Changing: Quick couplings facilitate fast, automated tool swaps, enhancing productivity.

- Hydraulic Actuators: High-pressure quick couplings enable seamless hydraulic power delivery to robotic systems.

- Pneumatic-Driven Automation: Quick couplings ensure smooth operation of pneumatic grippers and actuators in automated systems.

Metalworking and Machining

Quick couplings are indispensable in machining, stamping, and metal forming applications.

- CNC Machine Tool Changes: Quick couplings allow for rapid cutting tool swaps, improving machining efficiency.

- Hydraulic Forming Machines: Quick couplings simplify the reconfiguration of stamping and metal forming equipment.

- Cooling Line Management: Efficient coolant connections help extend tool life and maintain machining accuracy.

Key Benefits of Quick Couplings in Manufacturing

- Increased Efficiency: Quick couplings reduce downtime by allowing fast connections and disconnections.

- Enhanced Safety: Leak-proof designs minimize risks associated with spills and accidental disconnections.

- Durability and Reliability: Designed to withstand high pressures, extreme temperatures, and corrosive environments.

- Operational Flexibility: Enables rapid tool changes, reconfiguration of production lines, and easier maintenance.

- Leak and Spill Prevention: Automatic shut-off valves prevent fluid and gas loss during disconnections.

Conclusion

Quick couplings are indispensable in modern manufacturing, offering efficiency, safety, and adaptability across various industrial applications. Whether used in pneumatic tools, hydraulic machinery, fluid transfer systems, or automation, these couplings enhance productivity and ensure seamless operations. Investing in high-quality quick couplings leads to long-term operational benefits, reduced downtime, and improved workplace safety.

Leave a Reply