Hydraulic quick couplings are essential components across various industries, including manufacturing, agriculture, construction, and automotive sectors. They enable fast, secure, and leak-free connections between hoses, pipes, and equipment, ensuring efficient fluid transfer and minimal downtime. However, selecting the right quick coupling can be overwhelming due to the numerous types and configurations available. This guide will walk you through the key considerations, standards, and identification methods to help you choose the right hydraulic quick coupler for your needs.

(more…)Category: Tech-Talks

Quick Couplings are widely used in lots of industries. We will write some articles about the technology, guides and information.

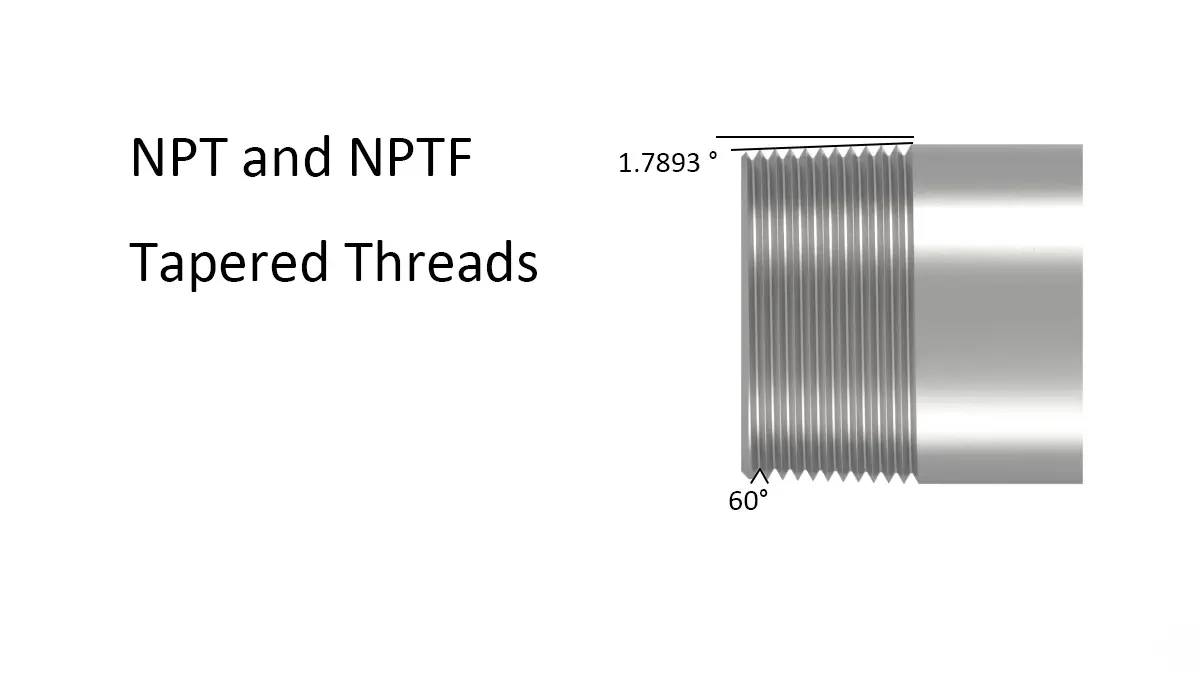

Understanding NPT and NPTF Tapered Threads for Leakproof Seals

When working with fluid or gas systems, selecting the correct type of threaded fitting is crucial for ensuring leakproof connections. Two common types of tapered threads are National Pipe Taper (NPT) and National Pipe Taper Fuel (NPTF). Understanding their differences and applications can help you achieve reliable, leak-free seals.

(more…)How to Install Quick Couplings: A Step-by-Step Guide

Quick couplings are essential components in many hydraulic and pneumatic systems, offering a convenient and efficient way to connect and disconnect fluid lines. Proper installation is crucial to ensure optimal performance and longevity of the coupling. In this blog, we’ll walk you through the steps to correctly install quick couplings.

(more…)

How to Measure Thread Size: A Comprehensive Guide for Choosing the Right Item

When it comes to purchasing threaded components such as bolts, nuts, or pipes, even the replace quick couplings, getting the correct thread size is crucial. An incorrect size can lead to fitting issues and potential damage. In this guide, we’ll walk you through the steps to accurately measure thread size, ensuring you buy the right item every time.

(more…)

Introduction to ISO Standards for Quick Couplings

Quick couplings are crucial components in fluid handling systems, enabling rapid connection and disconnection of fluid lines. The International Organization for Standardization (ISO) has established several standards to ensure compatibility, safety, and performance across various types of quick couplings.

(more…)

Understanding Thread Options for Quick Disconnect Couplings

Quick disconnect couplings, also known as quick couplers, are essential components in hydraulic systems, allowing for rapid and efficient connections and disconnections of fluid lines. One critical aspect of selecting the right quick disconnect coupling is understanding the thread options available. Threads ensure that the couplings fit securely with the system’s hoses, pipes, or other components, ensuring leak-free and reliable operation. In this blog, we’ll explore the various thread options for quick disconnect couplings and their applications.

(more…)

Choosing the Right Seal Ring Material for Quick Couplings

In the world of fluid transfer systems, quick couplings play a pivotal role in ensuring efficient and leak-free connections. A critical component of these couplings is the seal ring, which ensures a tight seal and prevents leaks. Selecting the appropriate seal ring material is crucial for the performance and longevity of the quick couplings. In this blog post, we will delve into the various seal ring materials used in quick couplings and their respective advantages.

(more…)

Gaskets and Seal Rings in Quick Couplings: Usages and Differences

Hydraulic quick couplings are essential components in hydraulic systems, allowing for the quick and easy connection and disconnection of fluid lines without significant fluid loss or contamination. Within these couplings, gaskets and seal rings play crucial roles in ensuring leak-free performance and maintaining the integrity of the hydraulic system. Here’s an overview of their usages and differences:

(more…)

The Ultimate Guide to Hydraulic Quick Coupling Materials

Hydraulic systems are the lifeblood of many industrial and mobile machinery applications, and the quick couplings used in these systems are critical components. These couplings allow for the swift and efficient connection and disconnection of hydraulic lines without fluid leakage or system contamination. One of the key factors that influence the performance and longevity of hydraulic quick couplings is the material they are made from. In this guide, we’ll explore the various materials used in hydraulic quick couplings, including carbon steel with zinc or zinc-nickel plating, brass, stainless steel, and aluminum, to help you choose the best option for your specific needs.

(more…)

The Comprehensive Guide to Zinc Nickel Plating vs. Zinc Plating

When it comes to metal finishing, choosing the right type of plating is crucial for the longevity, appearance, and performance of your components. Among the various options available, zinc plating and zinc-nickel plating are two popular choices. Most quick couplings are made of carbon steel because it is more cost-effective and can withstand high pressure. Hardened Carbon steel is often used for high-pressure quick couplings in hydraulic systems. However, corrosion resistance is the biggest drawback. Plating is often required. zinc plating and zinc-nickel plating are the two most common plating methods. Each has distinct advantages and specific applications where they excel. In this blog, we’ll delve into the differences between zinc plating and zinc-nickel plating, exploring their benefits, and helping you make an informed decision for your needs.

(more…)