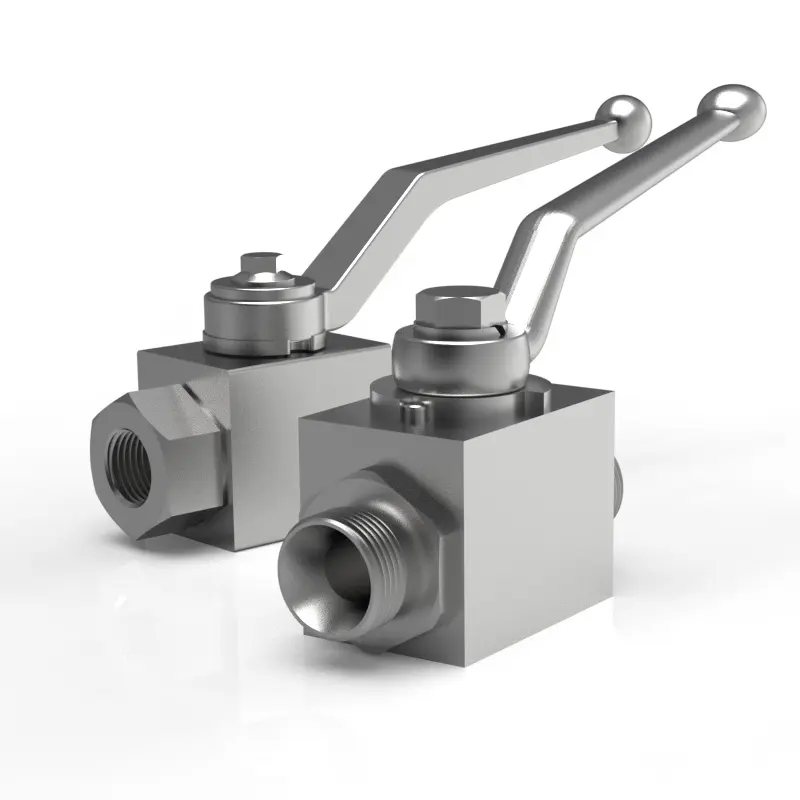

High Pressure Ball Valves – Designed for High-Pressure Performance

High Pressure Ball Valves are critical components in hydraulic systems, designed to control and regulate the flow of fluids under extreme pressure conditions. These valves are engineered to deliver optimal performance, ensuring the safe and efficient operation of systems where high-pressure fluid management is essential. Whether in industrial machinery, oil and gas applications, or hydraulic presses, high-pressure ball valves play a vital role in maintaining system integrity, preventing leaks, and optimizing flow control.

Classification and Series of High Pressure Ball Valve

KHB Series

2 way high pressure ball valves, have nominal pressure up to 7250 PSI.block type DN 04 – 25

KHM Series

2 way high pressure ball valves, the KHM, the construction is Forged type DN 32 – 50.

KHB3K Series

3/2-way change over ball valves with nominal pressure up to PN 500

KHP Series

Manifold mounted ball valves, 2/2-way manifold mounted ball valve (DN 06 – 50)

KHP3K Series

3/2- or 3/3-way manifold mounted ball valve (DN 06 – 50), PN up to 500 bar

KHB-F3/6 Series

KHB-F3/6 Series are SAE Flanged Ball Valves, Block-type ball valve DN 16-25